phildenholm

TS Member

- Favourite Ride

- Oblivion

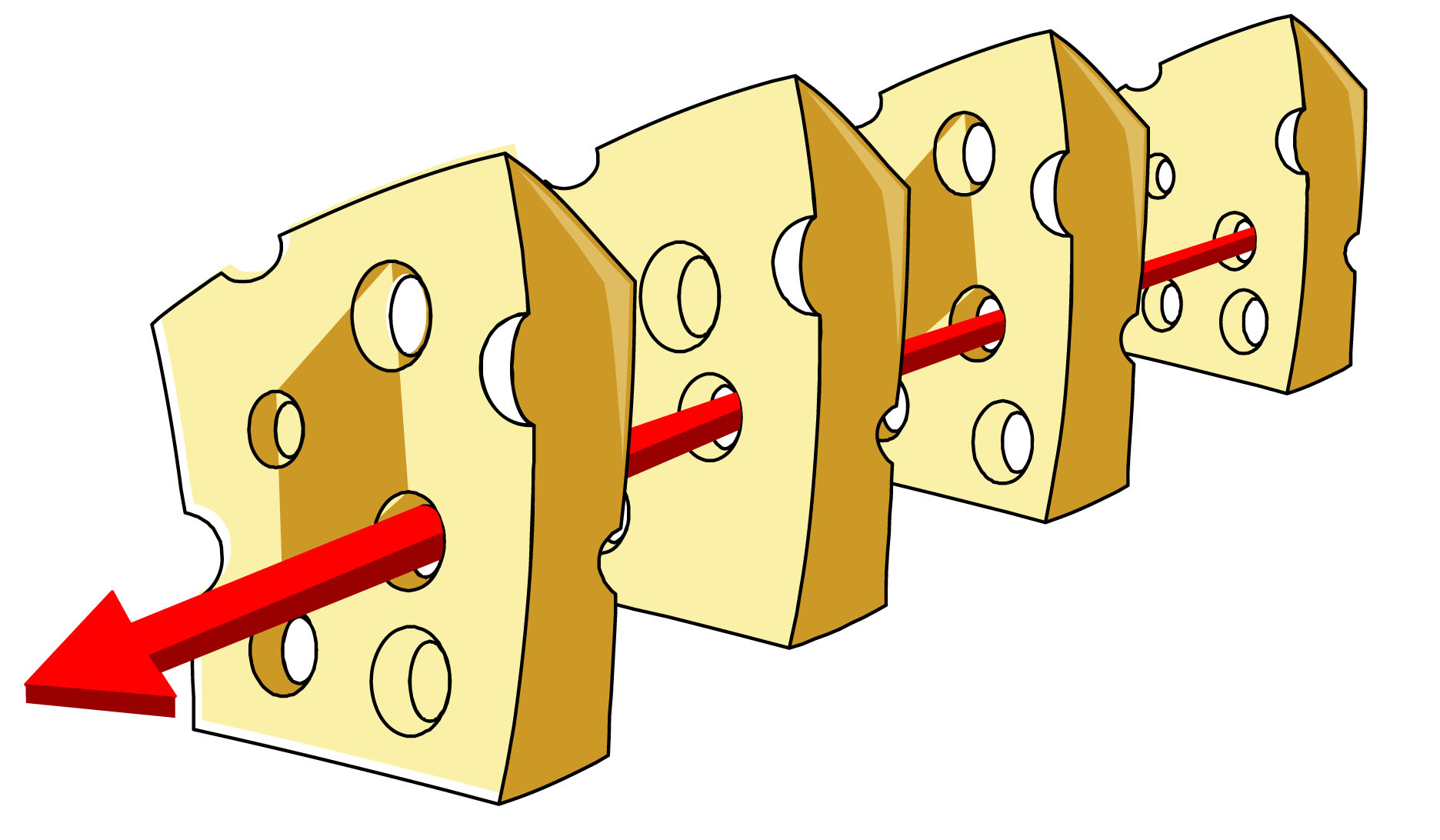

Is that what I said? A ride that stalls is badly designed but the stall shouldn't be a risk factor as the safety systems should prevent other trains entering that block, that's why the block system is the crux of this.

Any ride could stall if something affected a wheel bogie badly enough, hence why all coaster manufacturers plan for it even if they have no history of it.

I doubt the HSE or Merlin will see the stalled car as "not relevant" which is what you said IMO it is relevant and an issue that needs addressing before the ride can open again, can you imagine the panic the next stalled car would cause?